Torus is a Chennai-based team of passionate mechatronics engineers focused on advancing EV powertrain systems. We specialize in developing compact, high-efficiency solutions, with our core innovation being the scalable Torus Axial Flux Motors. Our 15-member team is dedicated to R&D, creating high-power-density motors that help vehicles go faster and farther. We believe in strong teamwork and a customer-first approach to drive innovation in EV technology.

- Core Technologies

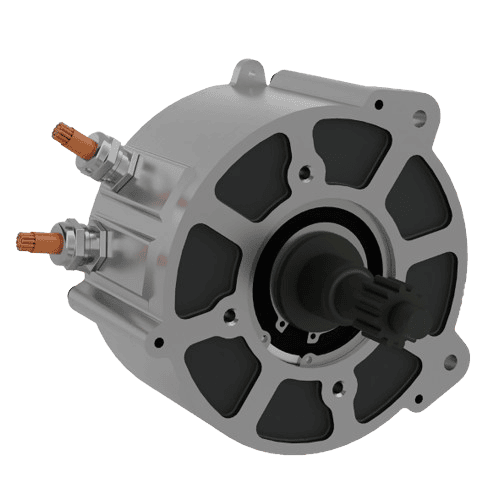

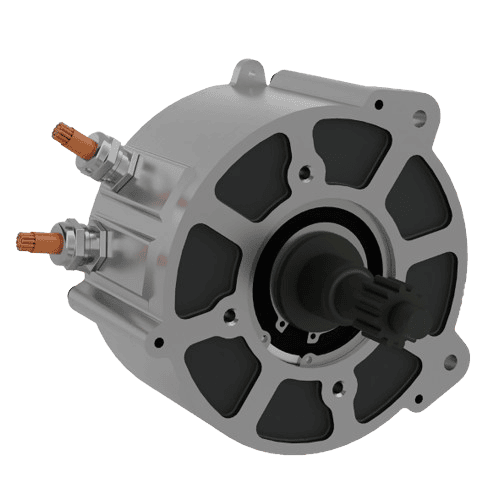

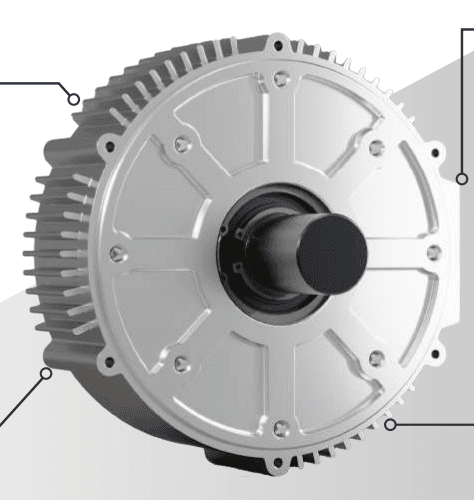

Torus Robotics flagship innovation is its axial flux motor technology, which offers several advantages over traditional radial

- Flux motors:

Compact and Lightweight: Up to 50% lighter, making them ideal for EV applications where space and weight are critical.

Enhanced Efficiency: Approximately 15% more efficient, contributing to better vehicle performance and range.

Cost-Effective: Designed to be more affordable, promoting wider adoption of EV technology.

These motors are tailored for various sectors, including automotive, defense, aviation, and consumer markets.

- Defense Innovations

In addition to EV components, Torus Robotics has made significant strides in defense technology. The company developed the Mobile Autonomous Robotics System (MARS), a fully electric unmanned ground vehicle (UGV), which was delivered to the Defence Research and Development Organisation (DRDO). This achievement marked Torus as the youngest startup to indigenously design, develop, and deliver India's largest fully electric UGV to the Indian defense sector.

- Funding and Growth

In February 2024, Torus Robotics secured $470,000 in seed funding led by the Tamil Nadu Infrastructure Fund Management Corporation (TNIFMC) through the Tamil Nadu Emerging Sector Seed Fund (TNESSF). Additional participation came from Forge Innovation & Ventures and the Society for Innovation & Entrepreneurship (SINE) at IIT Bombay. The funding is aimed at enhancing research and development, facilitating the transition of technologies from lab to market, and supporting overall business growth.

- Recognition and Impact

Torus Robotics has been recognized for its innovative contributions:

Awards: Won the BIRLA Global Innovation Challenge 2020 by Startup India & AIC Bimtech, standing out among 874 startup innovations from seven countries.

Sustainability: Their axial flux motors are projected to save up to 1,036,308 tonnes of CO₂ emissions annually, aligning with global efforts to combat climate change.

Torus Axil Flux Motors

Where Speed, Range and Affordability meets

Torus produces controllers and axial flux motors that are lightweight, small and have a high power density. Products from Torus offer outstanding performance and efficiency throughout a broad spectrum, with strong regenerative capabilities. With Torus, explore the future of motor technology where quality and innovation coexist.

SWOT Analysis

|

| ||||

|

|

| Overall rating | 3.7 |

| Market Traction | 4 |

| Sustainability | 3 |

| Innovation | 4.5 |

| Financial Health | 4 |

| Thought Leadership | 3 |

| Technical Specs | Air Cooled | Liquid Cooled |

| Voltage | 48/60/72 V | 48/60/72 V |

| Peak Power | 5.5/6/7 kW | 7.5/7.8/9.5 kW |

| Peak Torque | 36 Nm | 41 Nm |

| Max Current | 80 A | 180 A |

| Max RPM | 3600/ 4500/5400 | 3600/4500/5400 |

| Efficiency | 92% | 96/96/98% |

| Rotor Position Sensor | Magnetic Encoder | Magnetic Encoder |

| Weight | 7.5 kg | 7.8 kg |

| Technical Specs | Air Cooled | Liquid Cooled |

| Voltage | 48/60/72 V | 48/60/72 V |

| Peak Power | 8.5/10/12 kW | 11/15/17 kW |

| Peak Torque | 60 Nm | 80 Nm |

| Max Current | 230 A | 300 A |

| Max RPM | 3600/ 4500/5400 | 3600/4500/5400 |

| Efficiency | 94% | 97/97/98% |

| Rotor Position Sensor | Magnetic Encoder | Magnetic Encoder |

| Weight | 10.5 kg | 11.8 kg |

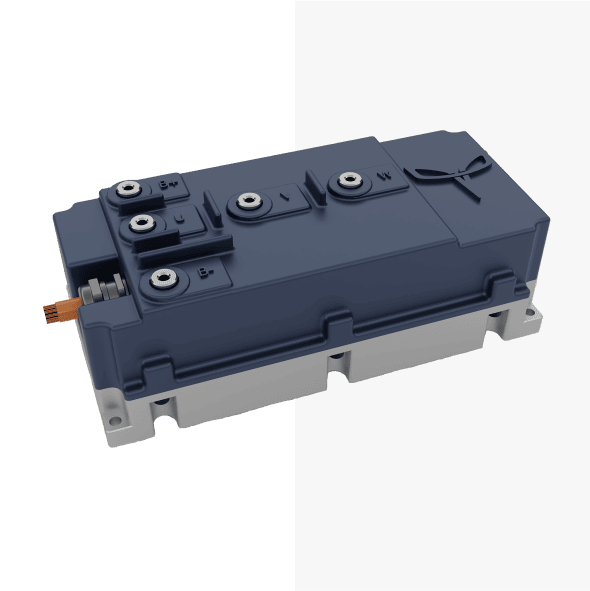

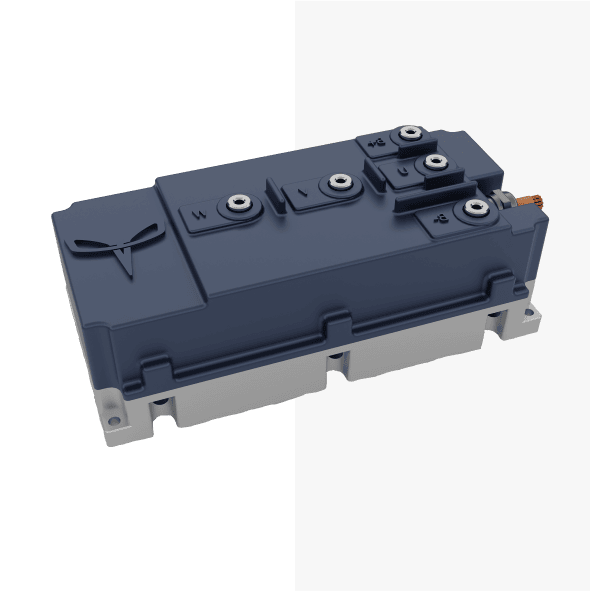

Torus Electronic Speed Controller (TESC)

| Technical Specifications | Details |

| Configurable For | BLDC/PMSM/IPM/AFM |

| Nominal Voltage | 40/60/72 V |

| Max DC Current | 80 A |

| Phase Peak Current | 250 A |

| Control Method | Sinusoidal/Trapezoidal |

| Weight | 1.3 kg |

| Interface & Communication | Wired, CAN, UART, Throttle |

| Features | Regenerative Braking |

| Technical Specifications | Details |

| Configurable For | BLDC/PMSM/IPM/AFM |

| Nominal Voltage | 40/60/72 V |

| Max DC Current | 120 A |

| Phase Peak Current | 350 A |

| Control Method | Sinusoidal/Trapezoidal |

| Weight | 1.3 kg |

| Interface & Communication | Wired, CAN, UART, Throttle |

| Features | Regenerative Braking |

Advantages of Choosing Torus

- Compact and lightweight motors

Its parallel magnetic flux path design, which improves magnetic field distribution and allows for significant weight and size reduction without sacrificing performance, is the reason why Torus Axial Flux Motors (TAFM) offer a great advantage with their 50% weight reduction and compact size.

- More Efficient

Because of the low energy losses during operation, Torus Axial Flux Motors & Controller reaches a 95% combined efficiency range, establishing new benchmarks in electric motor technology.

- Cost efficiency

Torus Axial Flux Motors (TAFM) are cost-efficient due to the utilization of unique materials and manufacturing processes, coupled with a reduction in overall material usage. This results in lowered production costs without compromising quality or performance, ensuring affordability and sustainability. Additionally, they are 10% more cost-effective compared to radial flux motors.

- Benefits of TAFM

With a motor architecture that is at least 50% lighter and 98% more efficient and incredibly economical, Torus Axial Flux Motors provide an unmatched power density.

- Application Benefits of using TAFM

Torus Axial Flux Motors offer several benefits when installed in automobiles, with a focus on lightweight design and efficiency. Notably, our motors have the greatest capacity for regenerative braking, which allows cars to travel up to 10% faster and further.